WHAT IF PLASTIC COULD TALK?

Give your plastic a voice!

TAGTEC

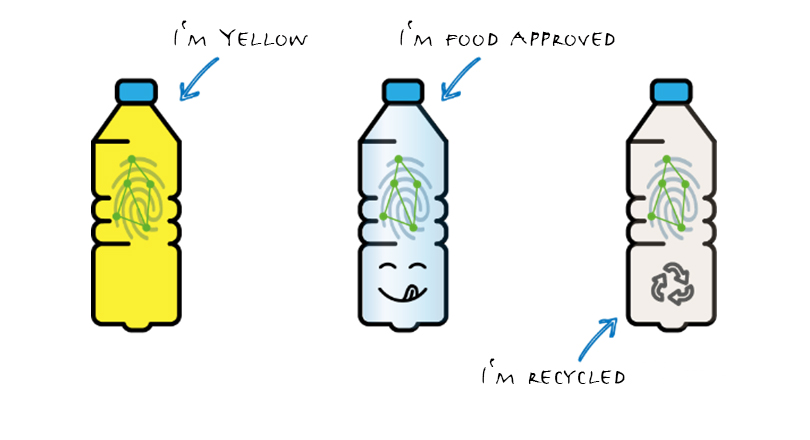

Let us introduce you to our new masterbatch product line TagTec. The name TagTec compounds both terms 'Taggant' and 'Technology'. It lifts the application possibilities of product authentication to the next level. The focus here lies on safety, traceability and automation of product processes. In other words, plastic parts are given an individual DNA – an identity signature like a fingerprint, which enables the documentation of an entire product. Therefore, all the stages of a product life cycle – from manufacturing, quality management, supply chain or circular economy of raw materials – are traceable. The information contained in the fingerprints can be read using special sensors that we have developed together with our partner. A key advantage of product authentication using TagTec is also the quality assurance of plastic products.

POSSIBLE APPLICATIONS

TagTec product authentication has numerous areas of application.

IMPORTANT: Our solutions are individually tailored to the needs of our customers!

TECHNICAL BACKGROUND INFORMATION

The fundamental principle of TagTec is based on two main pillars – encoding and decoding

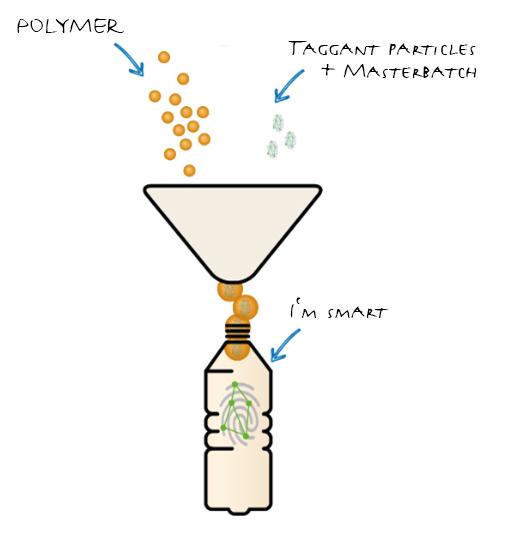

ENCODING

The polymer to be processed is equipped with ‘fingerprints’, which were previously added to the masterbatch via Taggant particles. It should be mentioned that every mixture is unique and tailored to the needs of our customers. This results in an intelligent plastic, which enables numerous fields of applications.

DECODING

There are two possible options for decoding the information contained in plastic parts: STAR and TAU.

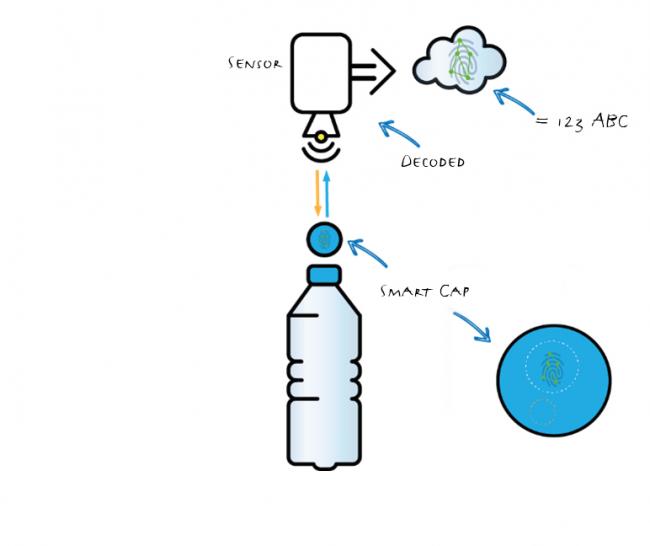

STAR

When decoding using Star, each individual plastic product has its own ID which is stored in a cloud memory. Here, detection takes place exclusively at a fixed spot on the reference surface, e.g. in the middle of a bottle cap. The most important point is that the reference area for encoding and decoding remains the same.

The sensor, which is connected to the cloud, illuminates the previously defined area of the plastic article using LED’s. The bottle cap immediately transmits the previously encoded information to the sensor.

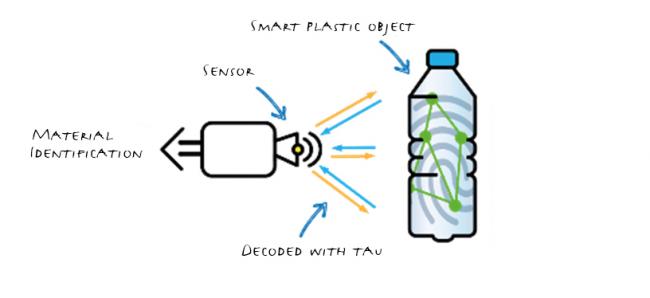

TAU

When decoding using Tau, the information can be read out from any part of the plastic product. The response signal, however, depends on the respective mixture of Taggant particles. Similarly to Star, the light is absorbed, emitted by Taggants and directly measured by the sensor.

TAGTEC DEMONSTRATION AT K 2019 IN DÜSSELDORF

The following two videos demonstrate the process of product authentication using TagTec.

VIDEO 1: PEGS

The video demonstrates how at WIBA’s partner booth polycarbonate is dyed using a colour masterbatch, as well as it is made identifiable and laser markable by adding a TagTec / laser marking combination batch. Here the production of pegs using injection moulding serves as an example of a product that is both stylish and complex at the same time. After production, the pegs are electronically registered by mobile STAR detectors and the associated codes and other information, such as the name ‘Maria’, are stored as items in a database via an app. After that, other detectors can then recognise the part and retrieve the stored information for this purpose. In the video, this is shown with an inline sensor at the Gabriel-Chemie stand. The read information ‘Maria’ is then transferred to the surface of the peg by the laser marking station of our cooperation partner beLaser.

VIDEO 2: INDUSTRIAL COMPONENT AUTOMOTIVE

Video 2 shows an industrial component detection using a black, highly filled PP-based carrier of a rear car seat unit. This is generated using STAR inline detectors in a fully automated, injection moulding process. During the extraction, the robot moves the components exactly to the reading position of the inline sensor, which then generates the electronic codes in the database. This way, for each component, all relevant data of the injection moulding machine can be saved from the production in operation. In addition, data about the material itself and its conditioning before processing on the component can also be recorded. Following the production itself, the station shows that all these data can be read or supplemented at any time at the defined surface section.

VIDEO 3: SORTING SYSTEM

While the first two videos focus on the detection of single parts, the material selection is illustrated here. By using TAU detectors, it is possible to identify various material-specific differences, different suppliers, etc. for the desired information that can be defined without requiring a database connection. This is accomplished with the sorting system of our cooperation partner Sensor Instruments, which identifies and sorts identically coloured bottles made of identical materials using TagTec masterbatch information that is stored.

It is not only possible to combine both methods - in many cases, this is even quite useful, as it allows you to record the product’s life cycle from production, along the entire supply chain to recycling and opens up many other possibilities for future applications.

Videos in cooperation with:

Sensor Instruments: https://www.sensorinstruments.de/

Wittmann Battenfeld: https://www.wittmann-group.com

beLaser: https://www.belaser.de/

We’d like to thank our cooperation partners Sensor Instruments, beLaser and Wittmann Battenfeld for their support!