intrinsic metallic shine in plastics

Our masterbatch formulas with ultra-fine pigments from effect pigment specialist Schlenk Metallic Pigments GmbH create a silky, homogeneous surface on the plastic object by means of mass colouration. The surface is free from visible glitter particles and characterised by an intense deep gloss, especially for high-gloss surfaces. This type of perfect surface can be cost-effectively achieved through mass colouration. We have adopted a unique position of quality in the metallisation substitution sector with our formulas and the high-grade effect pigments from Schlenk.

The exclusive small series of “Flowing Metallics” was created in ten elegant, distinguished colours as samples in a PP polymer and forms part of the current Colour Vision N°17.

The Range

NICKEL METALLIC GLOSS

dosage: E=2% in PP transparent

light: 7- 8

temperature: 300° C

product number: HP7BA5567METALLIC

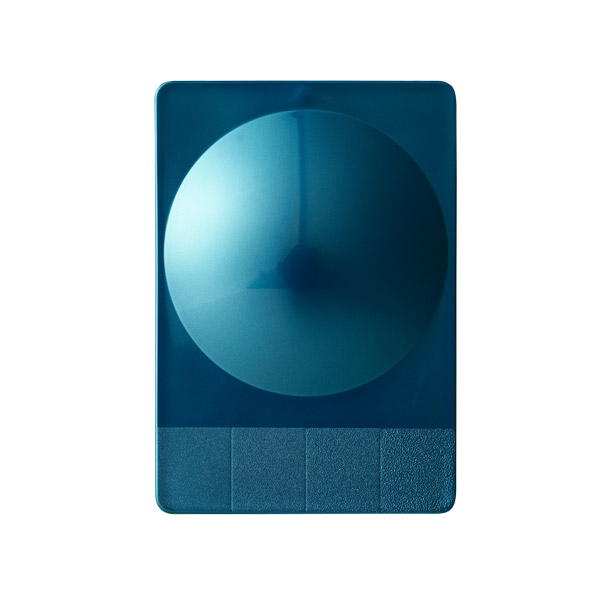

OCEAN BLUE METALLIC GLOSS

dosage: E=6% in PP transparent

light: 7- 8

temperature: 280° C

product number: HP5BB4417METALLIC

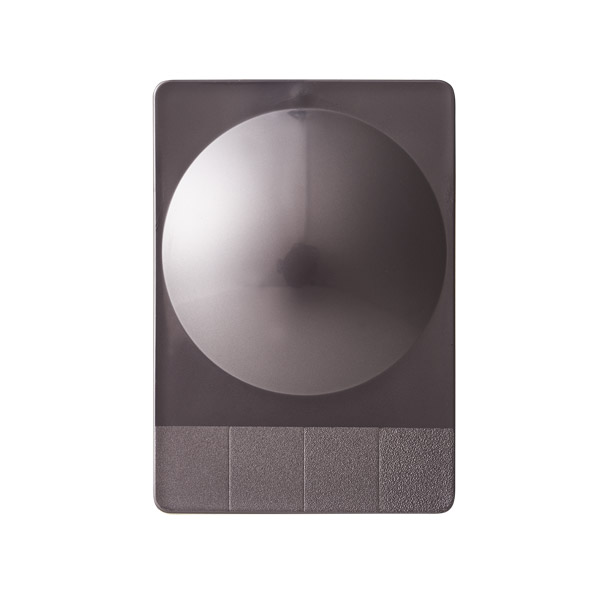

GRAPHITE METALLIC GLOSS

dosage: E=4% in PP transparent

light: 7-8

temperature: 280° C

product number: HP5BB4397METALLIC

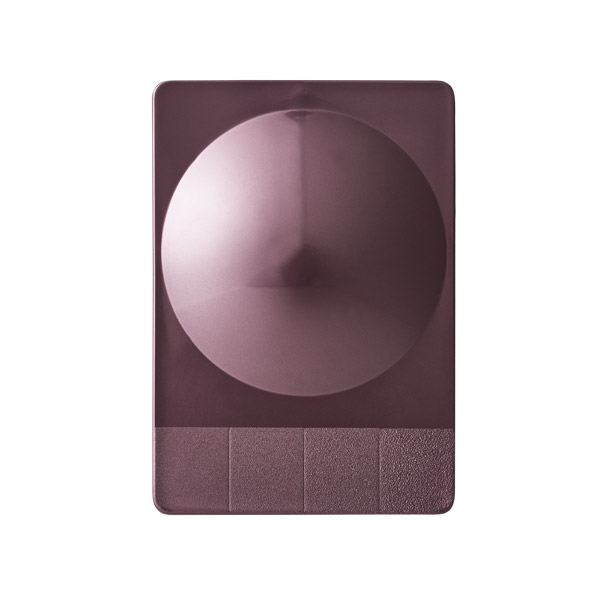

PLUM METALLIC GLOSS

dosage: E=3% in PP transparent

light: 7- 8

temperature: 280° C

product number: HP5BB4407METALLIC

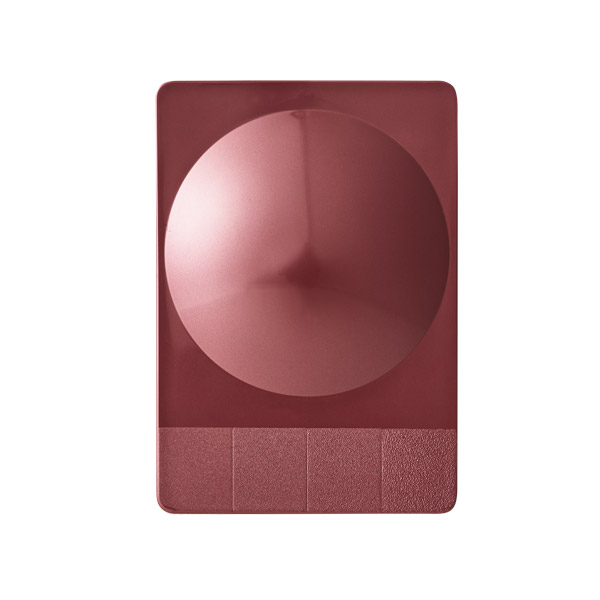

CALM RED METALLIC GLOSS

dosage: E=5% in PP transparent

light: 7-8

temperature: 280° C

product number: HP4BA9707METALLIC

PUCE METALLIC GLOSS

dosage: E=4% in PP transparent

light: 7-8

temperature: 300° C

product number: HP8BA4307METALLIC

FIR TREE METALLIC GLOSS

dosage: E=3% in PP transparent

light: 7-8

temperature: 300° C

product number: HP6BB0627METALLIC

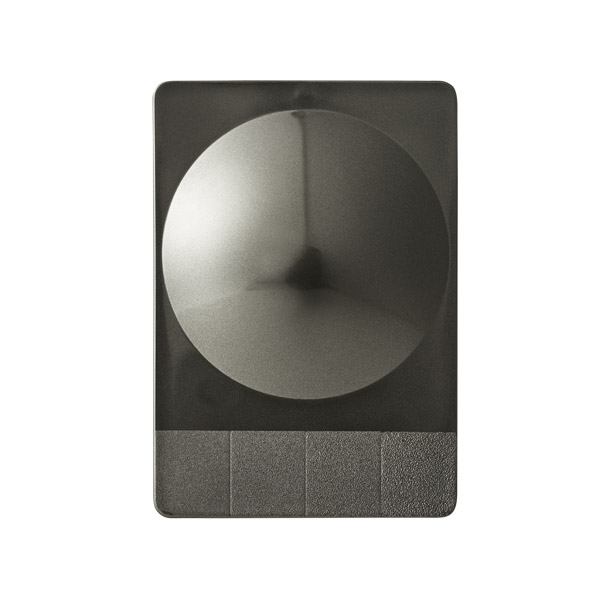

GUNMETAL BLACK METALLIC GLOSS

dosage: E=4% in PP transparent

light: 7-8

temperature: 280° C

product number: HP9BA8837METALLIC

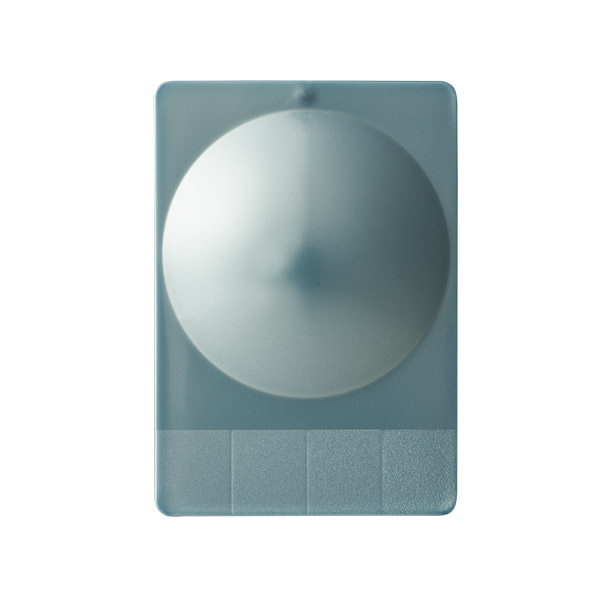

LIGHT BLUE METALLIC GLOSS

dosage: E=2% in PP transparent

light: 7-8

temperature: 300° C

product number: HP5BB1817

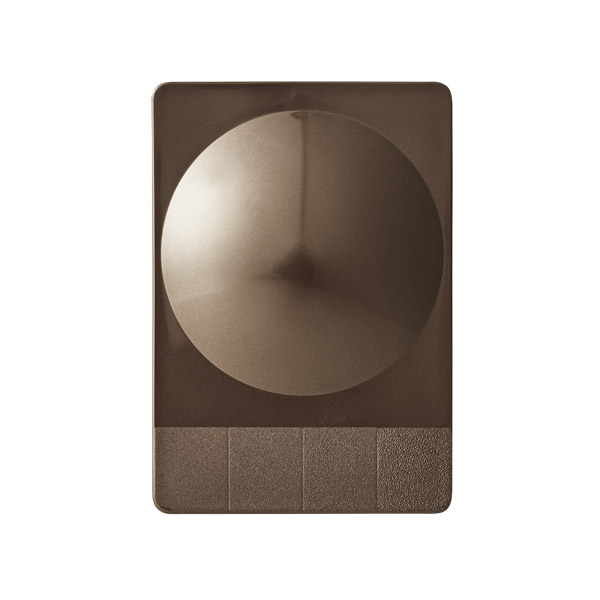

LIGHT BROWN METALLIC GLOSS

dosage: E=2% in PP transparent

light: 7

temperature: 290° C

product number: HP8BA4317

clear advantages

Our masterbatch can be used in many polymers and has already been successfully tested in a wide range of manufacturing processes. It is also approved for contact with food. This alternative offers benefits in packaging processing for numerous plastics packaging manufacturers, especially in the cosmetics industry, as additional logistical tasks and production steps can be omitted by doing away with the need for metallisation.

All the benefits of plastic packaging are retained, including the higher breakage resistance compared to other materials.

The masterbatch for all colours of the “Flowing Metallics” series can be used not only for cosmetics packaging but also for food packaging, household products and in the sports industry, and also turns lifestyle products into exclusive eye-catchers.

We are really pleased to be able to make an active contribution to the development of new effects and solutions for our customers with innovative products. The result of the cooperation with Gabriel-Chemie is setting new standards in the field of metallisation substitution, which we all can be very proud of.

impressed?

Are you impressed by the attractive look of metal and the advantages of our "Flowing Metallics"?

We will be pleased to show you a sample with our unique metallic effect which enables you to experience the intrinsic metallic shine with all senses.

We will be happy to advise you on your product ideas!