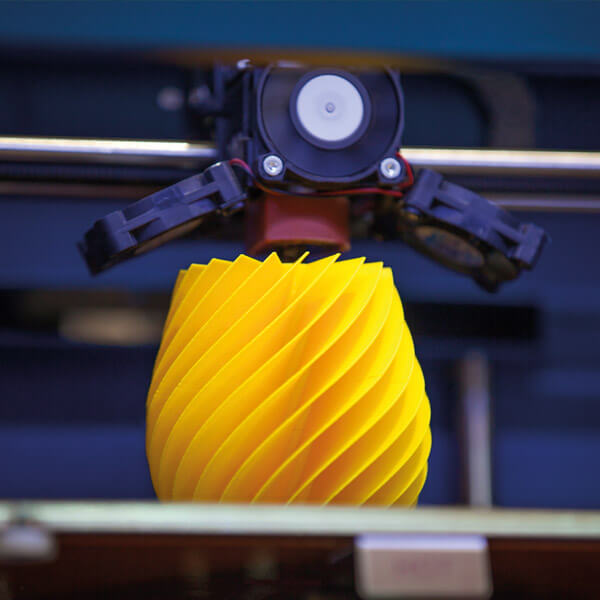

Masterbatch for 3D print filament

Fused Deposition Modelling (FDM) is professional technology for additive manufacturing. The possibilities now range from making a quick concept model or prototype, through to fully functional components for aviation or even the manufacture of artificial limbs.

Because of the increasing number of suppliers, this technology is now affordable for a broader target group and small gadgets or spare parts can be manufactured and made available for anyone with a very short lead-time. As a result of the use of high quality thermoplastics the printed parts provide outstanding mechanical, thermal and chemical properties.

Polymer Types for 3D Print

ABS

ABS is one of the most used materials in the FDM procedure. Thanks to its good mechanical properties the material is suited for manufacturing prototypes as well as technical parts (for example cogs).

PLA

PLA is seen as an environmentally friendly alternative to petrochemical-based plastics because it is manufactured by converting sugar and starch

from plant-based raw materials. After ABS, PLA-filament is the most commonly used material in the consumer 3D print-sector. The smooth surface, low warpage and great printing features make this thermoplastic an interesting alternative despite its inherent rigidity and brittleness. Further benefits are the lack of unpleasant odours during printing and the high sharpness of detail.

PETG

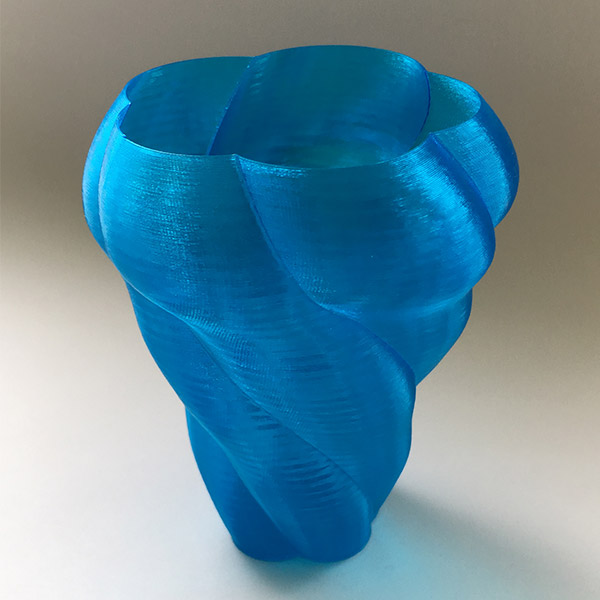

PETG is noted for its particularly high degree of transparency and low viscosity. As a 3D printing filament, it combines the positive properties of ABS and PLA.

All colours are noted for their particular brilliance and depth, even at low doses. They also have excellent temperature stability and can be processed at up to 240°C.

Masterbatch based on other polymer-carriers can be custom produced on request.

Colours & Effects

Glowing Ideas

Both polymers stand out because of their high colour brilliance, colour depth and excellent temperature resistance

(also when used with low dosage). For ABS and PLA we provide a wide range of standard colours and some innovative effects like fluorescent or phosphorescent colours and metallic shades.

Cool Decorations

Permanent laser marking is possible through adding our laser additive. As a result of our long-term experience in development and production of masterbatch we have developed a wealth of expertise in understanding the possible interaction between pigments, additives and polymers. Our know how provides you with the dimensional accuracy and process reliability you need.

Safety first

In Asia the number of suppliers of masterbatch for filaments is increasing, although their products are often supplied with no or incomplete accompanying documentation with important information on suitability for contact with food, UV-stability etc. Masterbatch from Gabriel-Chemie is manufactured in Europe according to ISO 9001, fulfils all relevant regulations (like REACH) and is delivered with the necessary documents and declarations of conformity. Therefore we ensure the final product is fit for purpose for the final application.