Quality as a certified process

The quality of our products and services has to meet the highest international and national criteria. Beyond that – and above all – it has to completely fulfil all customer expectations and customer-specific requirements. Tackling such constantly changing challenges successfully requires first and foremost an awareness of quality, which is dynamically cultivated and carried forward by all our employees across the entire Group.

Our quality management

Our approach to quality management ensures our high level of quality in the development and production of masterbatch for the processing of plastics. We operate a documented quality management system in accordance with the provisions of the international standards ISO 9001, 22000, 14001 and 13485. The certification and monitoring audits conducted by the TÜV and ÖVQ involve assessing whether our integrated management system meets these standards. The continuous improvement process and internal audits also ensure that our processes are constantly adapted and improved.

Certifications

further development results in ongoing process and procedural optimisations, which are implemented and confirmed as part of our EN ISO-9001 and EN ISO-14001 certifications.

- EN ISO 9001: Austria, Germany, United Kingdom, Hungary, Czech Republic, Italy and Spain

- EN ISO 14001: Austria, Germany, United Kingdom, Czech Republic

- Further highlights of our headquarters in Austria are the EN ISO 13485 certificate for medical products and the EN ISO 22000 certificate for food safety

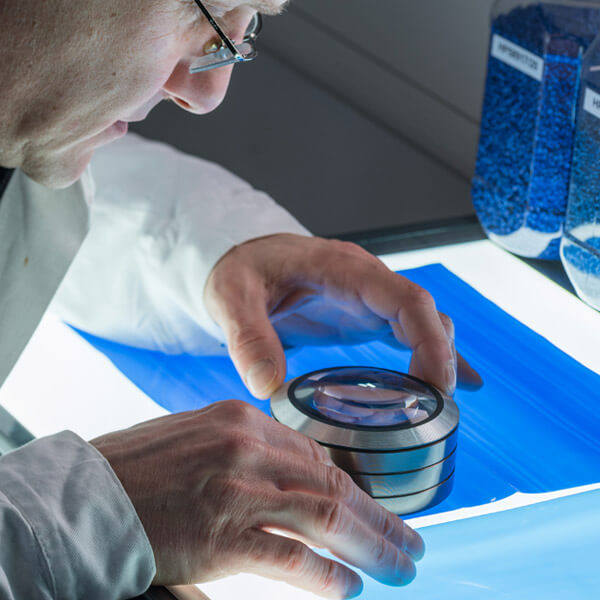

Our quality control

In order to ensure the quality of our products, the raw materials are subject to stringent quality control after the goods have been received and the finished products then also undergo a careful examination. This involves the random sampling of products followed by a comparison of the initial values with the current values in our laboratory. This process enables us to determine the extent to which products meet the stipulated quality requirements. We have a wide range of modern test equipment available for the quality control which enables us to analyse various parameters.

360° TECHNiCAL EXPERTiSE

Critical to our success is the further development of our core competencies, formulations and masterbatch production. We are constantly working on improvement measures in our own laboratories, while ensuring high quality standards. Around 100 technical employees optimize existing products and develop new recipes and formulations in careful consultation with our customers.

The technical departments of Product Stewardship, Research & Development, Colour Center & Service, Additive Center & Service and Technical Service & Applications form the core of our company. Numerous interfaces between these departments ensure the ideal transfer of knowledge – all to the benefit of our customers. A large number of our technical employees can look back on many years of experience at Gabriel-Chemie, and they constitute an integral part of our success.

Product Stewardship

The basis for the safe use and handling of chemicals – whether it is in our production process or at our customers – is extensive and up-to-date expert knowledge which our PSS department is responsible for. Aside from issuing safety data sheets and conformity declarations, we offer our customer expert advice on how to use our products worldwide in accordance with legal requirements. PSS is the expert point of contact for all product-related issues in relation to the assessment of raw materials in the production process and for issues concerning food law, chemicals law and other applicable laws.

RESEARCH & DEVELOPMENT

Research & development is a certified process in our group, which is not restricted only to the various locations. We involve international customers as well as suppliers and cooperate closely with renowned research institutes on a range of development processes. The close cooperation with our research partners enables us to continuously make major advances.

Colour Center & Service

Our Colour Center & Service employees are responsible for colour matching, analyses and quality control and are the main point of contact for enquiries from our customers. All colourants and effects are assessed in terms of their properties and quality as part of the raw material evaluation. Various tests are conducted in the modern laboratory in conjunction with AC&S for customers and the entire group. We can offer a wide range of samples for our customers in order to demonstrate the colour of the final product.

ADDITIVE CENTER & SERVICE

The Additive Center & Service department tests new raw materials, makes recommendations for formulations and produces combination products from colours and additives in cooperation with Colour Center & Service. The tasks of AC&S also include enhancing formulations and production processes. The careful analysis of complaints helps to increase knowledge and, of course, ensures their prevention in future. The department has state-of-the-art laboratory equipment. The standard procedure includes DSC analyses (Differential Scanning Calorimetry), TGA analyses (Thermogravimetry), spectroscopic methods such as IR or UV-VIS spectroscopy, rheological tests with a plate-plate rheometer and a weatherometer for accelerated artificial weathering.

TECHNICAL SERVICES & APPLICATIONS

This is where the knowledge from the four technical departments mentioned above confluences. Our TS&A department helps distributors and customers with product recommendations according to the intended area of application and requirements. Its other tasks include the issuing of technical documents along with acceptance test certificates and confirmations in relation to specific characteristics such as compatibility with foodstuffs. In the case of complaints, TS&A offers support with root cause analysis and future prevention. It has an extensive archive of all international standards in order to be able to meet the differing legal requirements of other states.

Visualizing your end product

We have an extensive machine park available for demonstrating end products. We also have blown and cast film extrusion lines, injection moulding machines and PET stretch blow moulders as well as our own preform mould and our own extrusion blowing system for hollow bodies. As a pioneer of innovation, we also have our own coffee capsule mould, a fibre manufacturing facility for PP fibres and Nd:YAG laser equipment.