Inspired by nature

New technical ideas and solutions as well as the trend towards individualisation are taking on an increasingly important role in the world of plastics. New materials, surfaces and shapes impress the consumer and stand out at the “point of sale”.

"Perfect Imperfection" is an effect series where shapes and structures formed over the years by nature are emulated in plastic in ways never seen before. More precisely, it involves the representation of onyx, marble, oxidised metals and even concrete in numerous colour combinations. These will be showcased during Colour Vision No. 17, the annual trend preview from Gabriel-Chemie. Previously unachieved effects in plastic such as marble veining, wood grains, oxidation processes and stone surfaces are achievable in plastic for the first time. Such creativity has virtually no boundaries. The effects represent provoked individuality, controlled randomness and an imaginative range of colours. These impressions can be achieved in PP and HDPE.

The Range

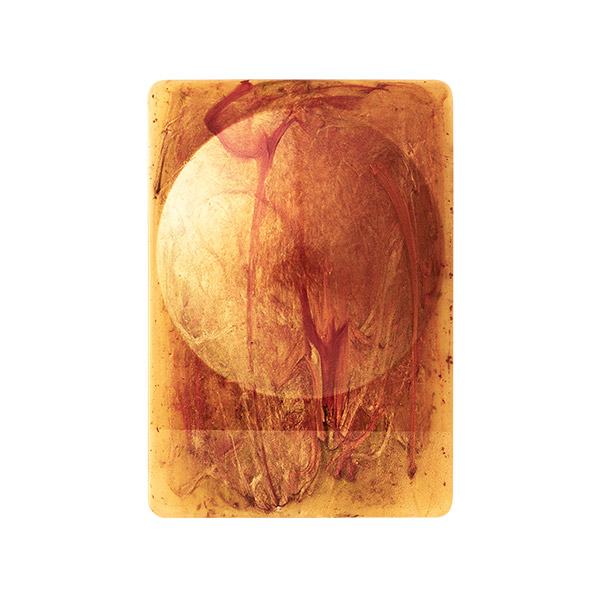

FIRE GOLD

dosage: E=10% in PP Spezial

light: 7- 8

temperature: 260° C

product number: UNS7BA5707MARBLE

copper gold shift

dosage: E=15% in PP Spezial

light: 7- 8

temperature: 300° C

product number: UNS7BA5697MARBLE

MAGMA RED

dosage: E=12,5% in PP Spezial

light: 7- 8

temperature: 300° C

product number: UNS4BA9847MARBLE

red orange camouflage

dosage: E=11,5% in PP Spezial

light: 7

temperature: 280° C

product number: UNS4BA9787MARBLE

black white camouflage

dosage: E=11 % in PP Spezial

light: 7 - 8

temperature: 300° C

product number: UNS9BB1317MARBLE

SPACE SILVERBLACK

dosage: E=6% in PP Spezial

light: 7-8

temperature: 300° C

product number: UNS7BA5637MARBLE

ONYX PEARL GOLD

dosage: E=5 % in PP Spezial

light: 6-7

temperature: 290° C

product number: UNS1BA4457MARBLE

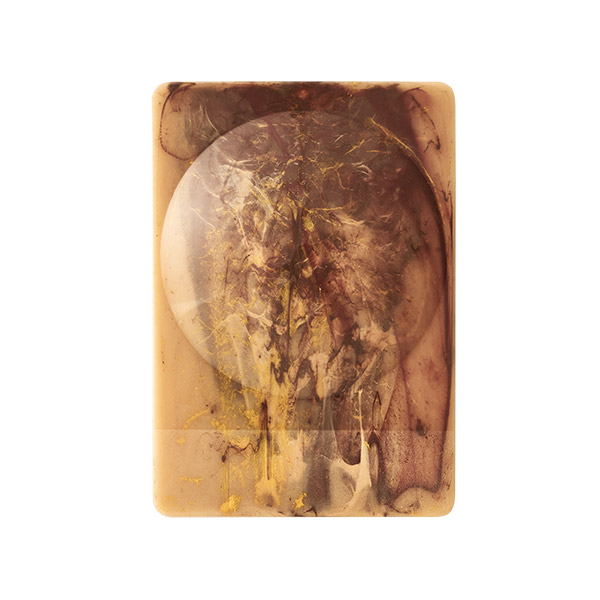

ONYX BROWN GOLD

dosage: E=5,5% in PP Spezial

light: 6-7

temperature: 260° C

product number: UNS7BA5627MARBLE

OXIDIZED COPPER GOLD

dosage: E=8 % in PP Spezial

light: 6-7

temperature: 290° C

product number: UNS7BA5657MARBLE

RUSTED SILVER

dosage: E=7% in PP Spezial

light: 7-8

temperature: 280° C

product number: UNS7BA5717MARBLE

green rust silver

dosage: E=7% in PP Spezial

light: 7-8

temperature: 280° C

product number: UNS7BA5667MARBLE

CONCRETE GREY

dosage: E=7% in PP Spezial

light: 7-8

temperature: 300° C

product number: UNS9BB0477MARBLE

Our know-how - your Service

We also develop your preferred colour variation on request.

These effects are achieved thanks to the extraordinarily high level of expertise of our colourists. The outstanding marble effect is obtained through the careful selection of polymers and the master batch recipe. It also involves the accurate adjustment of the processing machinery, essential in itself for a perfect final result. The advice of our specialists is indispensable here. These effects are at their most spectacular during the injection-moulding process. Almost every colour used for the marble and onyx effects is suitable for the manufacture of foodstuffs (in accordance with Decree 1935/2004 EC).

Innovative product strategies are the basis for long-term market success. Consumers don’t just expect an impeccable product, they also want to be addressed personally and experience the product and its packaging with all their senses. New technical ideas and solutions as well as the trend towards individualisation are taking on an increasingly important role in the world of plastics. New effects such as marble, onyx and oxidation impress the consumer and stand out at the point of sale.

impressed?

Do you want to give your products uniqueness and differentiation?

We will be happy to advise you on your product ideas!